Key Technologies for Analyzing Agricultural Machinery Clutch Friction Plates

In the precision transmission systems of modern agricultural machinery, clutch friction plates play a critical role. As the core component of the clutch, friction plates precisely control power transmission and disengagement through engagement and disengagement with the pressure plate, ensuring smooth operation of agricultural machinery under various working conditions. Operating in complex environments, they endure immense friction and thermal loads. Consequently, friction plates are not only key to performance but also typical wear parts. Typically, when wear reaches the design limit (such as when the groove depth is reduced to half its original value), replacement is necessary to maintain system reliability and safety.

High-Performance Paper-Based Friction Materials: The Preferred Choice for the Agricultural Machinery Market

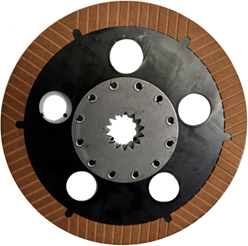

As agricultural machinery evolves toward higher horsepower, greater efficiency, and enhanced adaptability to harsh operating conditions, the performance requirements for clutch friction materials are becoming increasingly stringent. Paper-based friction materials are gradually emerging as the mainstream choice in the market due to their outstanding comprehensive properties—including high friction coefficient stability, excellent heat resistance, lightweight design, and cost-effectiveness. With years of deep expertise in friction materials and a precise understanding of the agricultural machinery market, our company has successfully developed a comprehensive range of clutch friction materials tailored to diverse requirements. Notably, for high-horsepower machinery and demanding operational environments, we offer high-performance materials. These materials have earned widespread recognition and trust from numerous customers due to their exceptional wear resistance, thermal fade resistance, and consistent bonding quality.Typical agricultural machinery friction plate image

Insights and Mitigation: Common Friction Disc Failure Modes

To ensure long-term stable operation of the clutch system, it is crucial to thoroughly understand and mitigate common friction disc failure modes. For paper-based friction discs, the following three typical failure mechanisms are predominant:a) Impact on the roughness of the mating steel plate: The surface roughness of the steel plate directly affects the friction coefficient, particularly exerting a significant influence on the static friction coefficient. Excessive roughness not only accelerates wear but may also cause noise issues. Therefore, selecting steel plate roughness matched to the friction material is fundamental to ensuring performance and longevity.

b) Overheating Failure: Overheating is a common cause of friction plate failure, triggered by factors including:

• Excessively high system energy per unit

• Insufficient or poor-quality cooling lubricant supply.

• Inadequate system heat dissipation design (e.g., thicker steel plates can enhance heat dissipation efficiency).

Overheating typically causes the following failures:

• Black scorch marks appear on the steel plate surface, leading to deformation or even warping.

• Accelerated premature wear of the friction material.

• Glazing on the friction material surface, resulting in loss of friction properties.

c) Excessive Surface Pressure Failure: Excessive surface pressure can cause the following damage to paper-based friction materials:

• Induce fatigue failure: Paper-based materials consist of multiple fibers; high pressure can fracture their fiber structure, causing loss of friction functionality.

• Accelerate premature compression and wear: Due to the material's porosity, high pressure causes premature deformation and wear of its structure.

• Cause localized thermal load concentration at high power densities: High pressure shortens engagement time, forcing energy release into a shorter duration and significantly increasing the risk of localized overheating.

Therefore, key measures to prevent such failures include: rationally designing the number and size of friction pads, ensuring adequate oil flow, and precisely controlling operating pressure.

Professional Commitment and Outlook

As a seasoned manufacturer in the friction materials industry, our company remains committed to delivering customized high-performance solutions that effectively address diverse complex application challenges. We not only provide products of exceptional quality but also leverage our deep expertise and experience to offer technical consultation and failure analysis support. Customer satisfaction and trust are our unwavering goals. We extend our sincere gratitude to our valued customers for their long-standing support and loyalty, and warmly welcome new clients to experience our products. We are confident that with our outstanding products and professional services, we will become your trusted long-term partner.

What performance tests are required for wet clutch friction plates?

What performance tests are required for wet clutch friction plates?

What consequences may arise from the deterioration of friction plates within a bulldozer's transmission?

What consequences may arise from the deterioration of friction plates within a bulldozer's transmission?

A Casual Discussion on Brake Pad Friction Materials

A Casual Discussion on Brake Pad Friction Materials

Prevent Downtime! Marine Anchor Brake Band: Fault Diagnosis, Repair & Proactive Maintenance Solutions

Prevent Downtime! Marine Anchor Brake Band: Fault Diagnosis, Repair & Proactive Maintenance Solutions